Overview of Industrial Timing Belt Materials and Models

Industrial timing belts are widely used in mechanical transmission, with their material and model directly affecting transmission efficiency and durability. Common timing belt materials include chloroprene rubber (CR), polyurethane (PU), and fluororubber (FKM). Chloroprene rubber offers strong oil and wear resistance, making it suitable for general industrial environments. Polyurethane timing belts provide higher tensile strength and aging resistance, ideal for precision equipment and high-load applications.

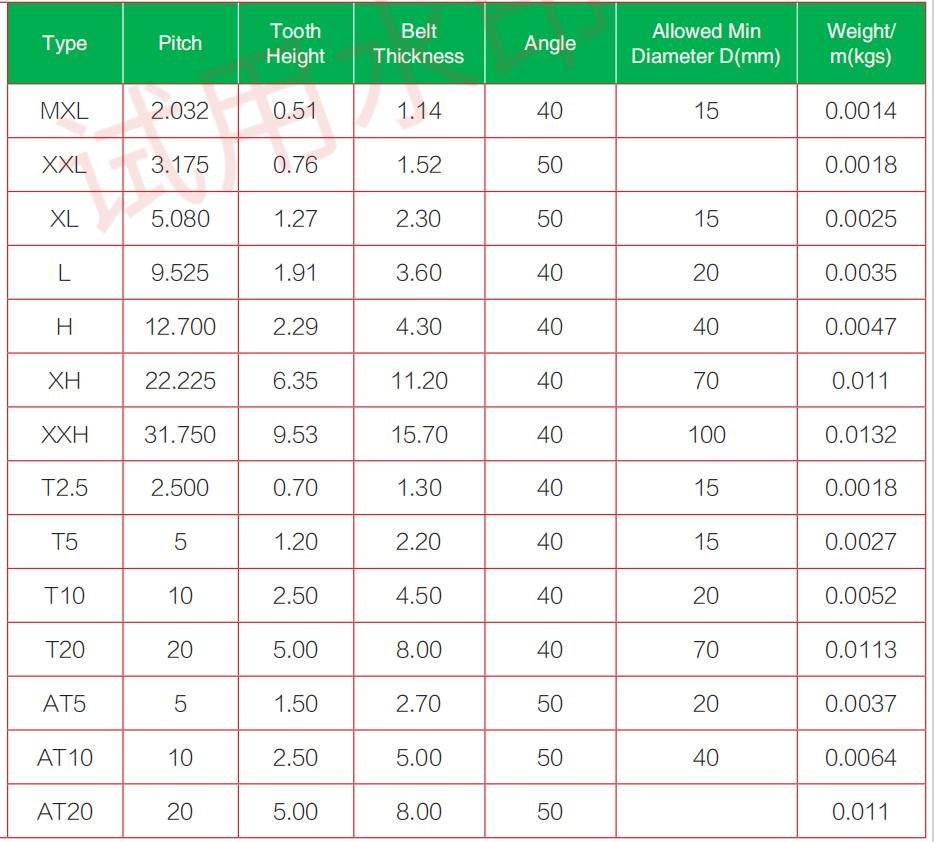

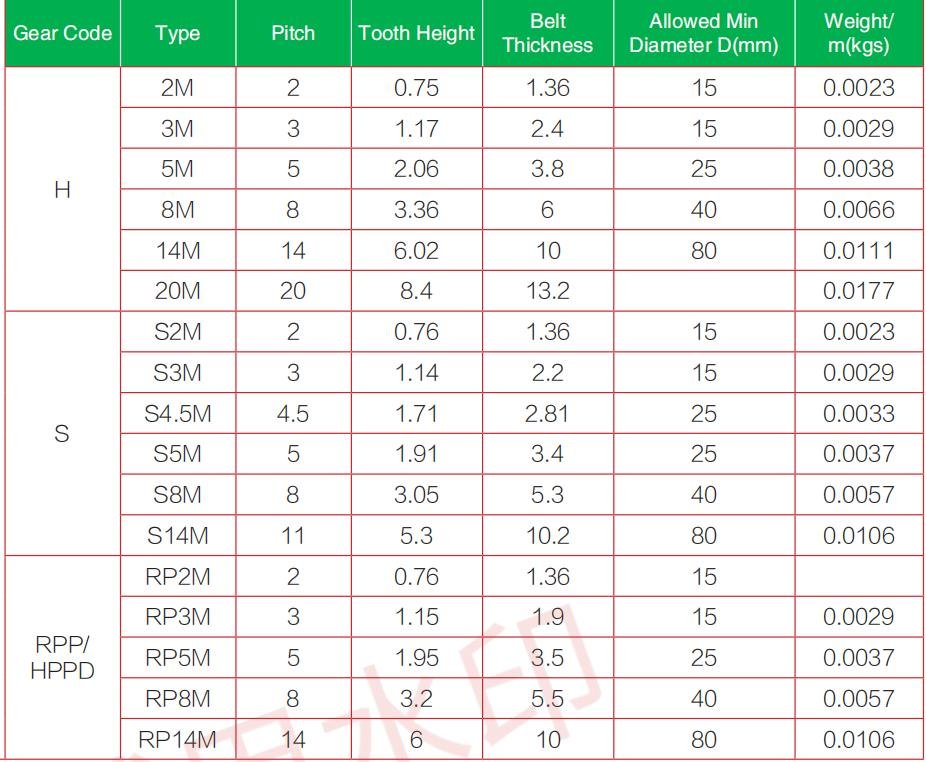

Timing belt models are mainly distinguished by tooth shape and pitch, such as T-type, HTD-type, and STPD-type. T-type timing belts have trapezoidal teeth and are suitable for low-to-medium-speed transmissions, while HTD-type (High Torque Drive) belts feature circular arc teeth, making them better suited for high-speed, heavy-load environments. Additionally, STPD-type timing belts offer higher precision, making them suitable for high-accuracy positioning applications.

Selecting the appropriate timing belt requires a comprehensive evaluation of the working environment, load, and transmission needs, thereby enhancing equipment stability and extending service life.